Phosphate based Intumescent Seal

High Performance

Support size customization

Low Maintenance Cost

With fire test certification

Product Brochure: DOWNLOAD

- Introduction

- Description

- Application

- Specifications

- Advantage

Introduction

The BIYOU Phosphate based Intumescent Seal that expands pressure-free,forming a heat-resistance isolution mass in case of fire. It fills gaps and cavities and builds up a very effective barrier agaist fire and smoke. This is a halogen free products which can be lamited with a self-adhesive tape and with PVC-foil in different colours.

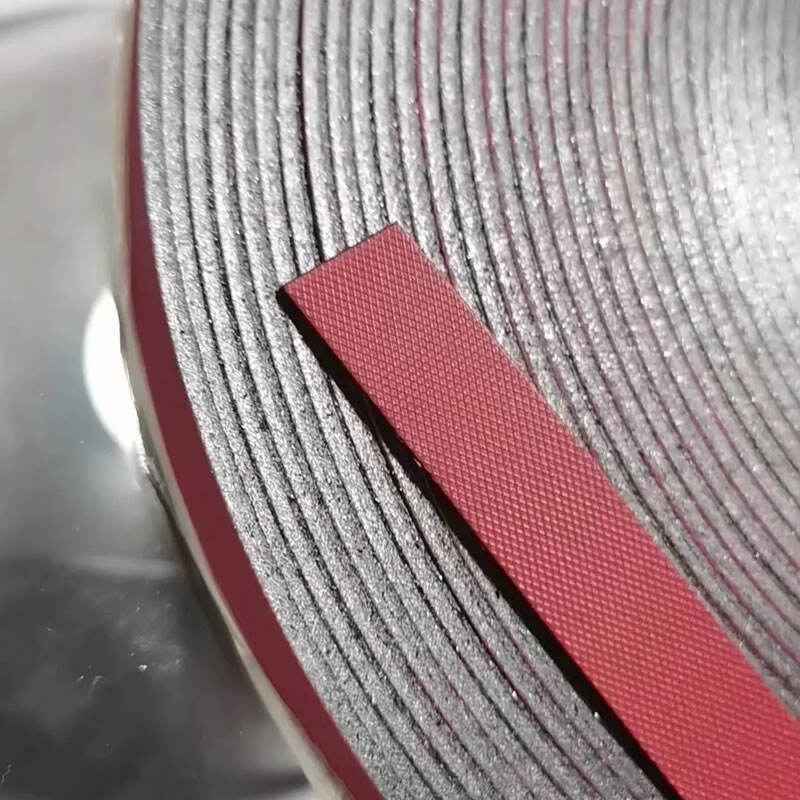

Description

The BIYOU Intumescent flexible Fire Tape designed to seal the air spaces between doors, frames and glass to help prevent the spread of fire, smoke, toxic gases and other byproducts from penetrating into adjacent areas. Intumescent materialexpand more than 30 fold when heatedand forms a hard char when exposed to heat. This flexible intumescent tape can be quickly cut to required sizes.

Application

The BIYOU Intumescent flexible Fire Tape developed for a wide range of applications where an intumescent material is necessary to maintain the system integrity and insulation in case of fire. These systems are for example;

1, fire doors and shutters

2, partition walls

3, glazing elements, ceilings and floors

4, fire safes and document cabinets

5, air grilles and dampers

6, pipe penetrations and cable transit systems

Specifications

| Density | approx. 1.35 g/cm3 |

| Expansion temperature | starting from 200°C |

| Expansion factor | up to 60-fold its original thickness |

| Expansion pressure | startapprox. 0 N/mm² |

Below is some of the regular sizes, we support size customization.

Advantage

1,The surface could with or without the fibro mesh

2,Could be supplied with or without an acrylic self-adhesive backing.

3,Intumescent material is high-pressure and multi-directional.

4,Intumescent material is totally unaffected by water, robust, non-flaking and difficult to tear.

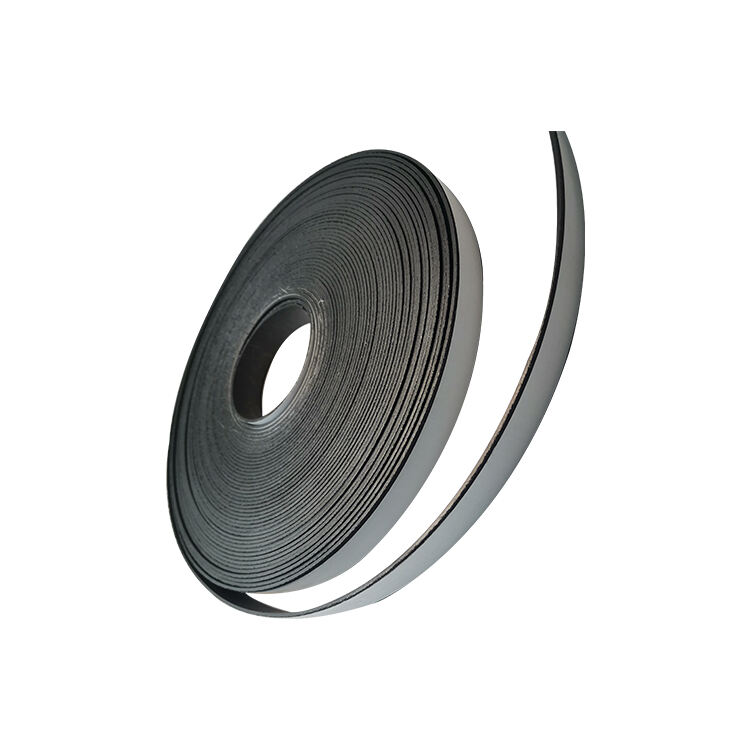

5,Intumescent material is black in color

6, It have been extensively tested in the UK, Europe and worldwide, to national and international standards.

Which meets the requirements forAS 1530.4:2014, BS 476 Part 22, EN 1634-1: 2014 and UL 10C (2009)

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

SV

SV

ID

ID

UK

UK

VI

VI

GL

GL

HU

HU

AF

AF

MS

MS

GA

GA

CY

CY

BN

BN

LA

LA

UZ

UZ